Supreme Info About How To Draw A Value Stream Map

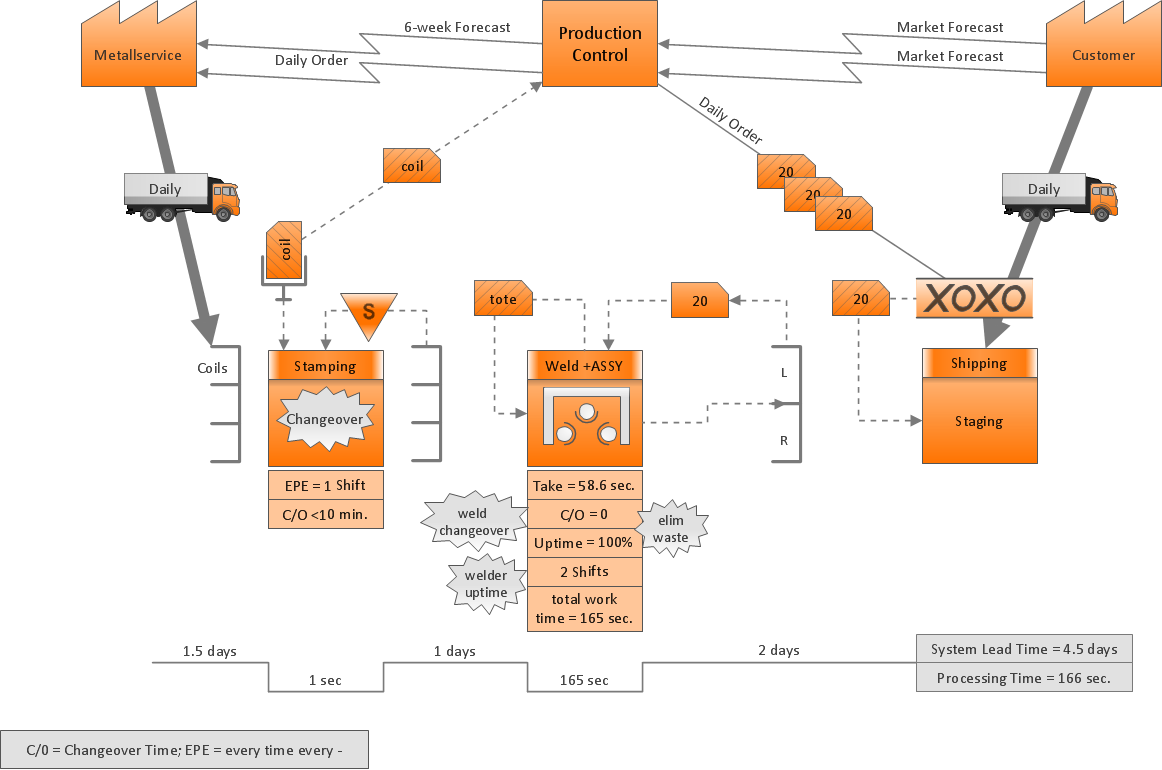

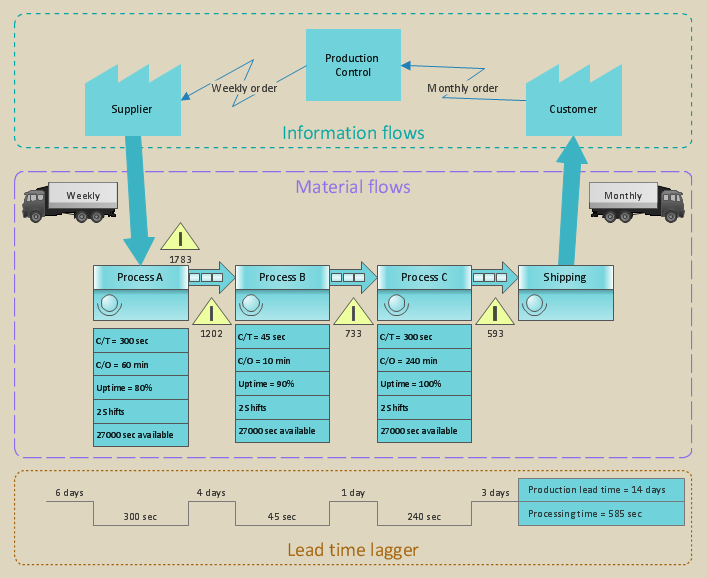

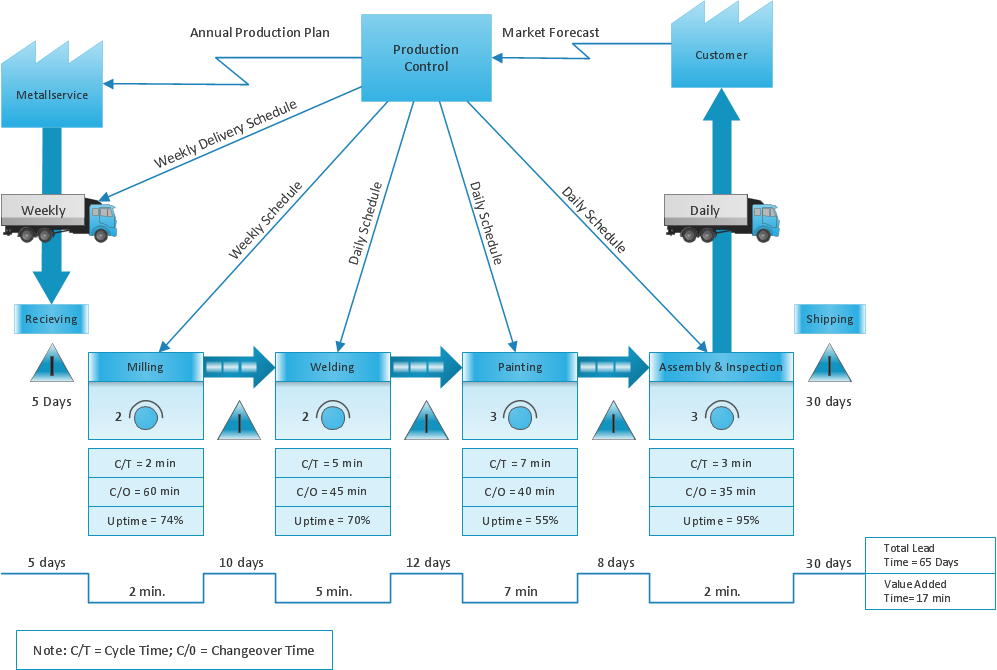

Value stream mapping (vsm) is a powerful tool for lean manufacturing that helps you visualize and analyze the flow of materials and information from the supplier to.

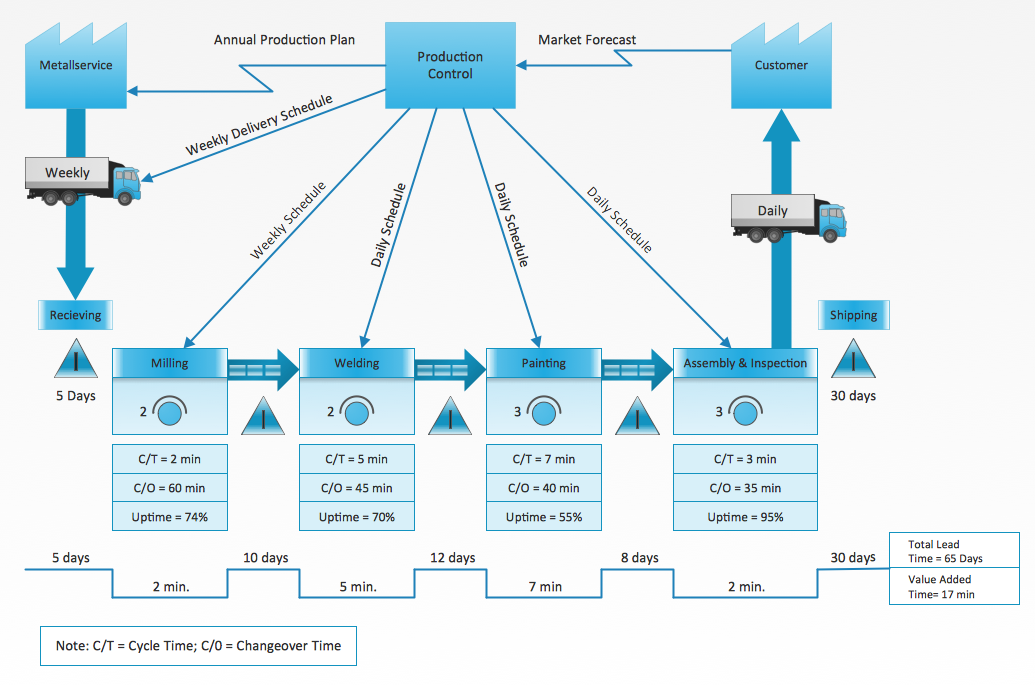

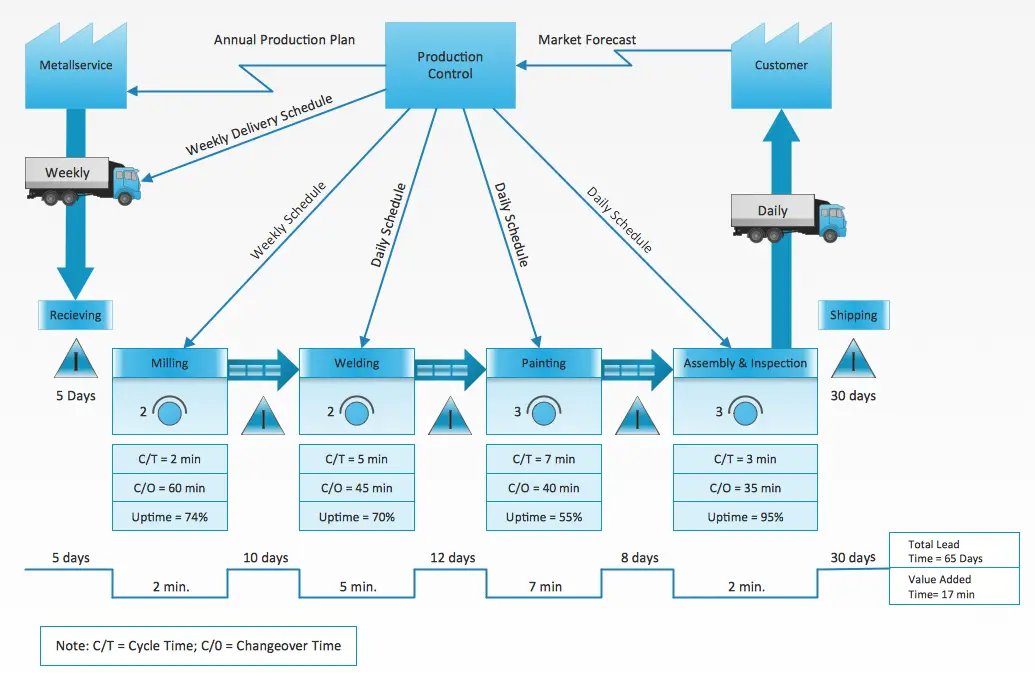

How to draw a value stream map. A typical process is to draw a current state vsm and then model a better way with a future state and/or ideal state vsm. A value stream map keeps a running total of the timeline data in the timeline summary box. To actually draw the map, you can use:

This is a step by step guide to creating a current state value stream map, the first step in working towards your ideal state value stream and a truly lean system. At the kaizen event, the team must complete four important steps: Click on any of these value stream maps included in smartdraw and.

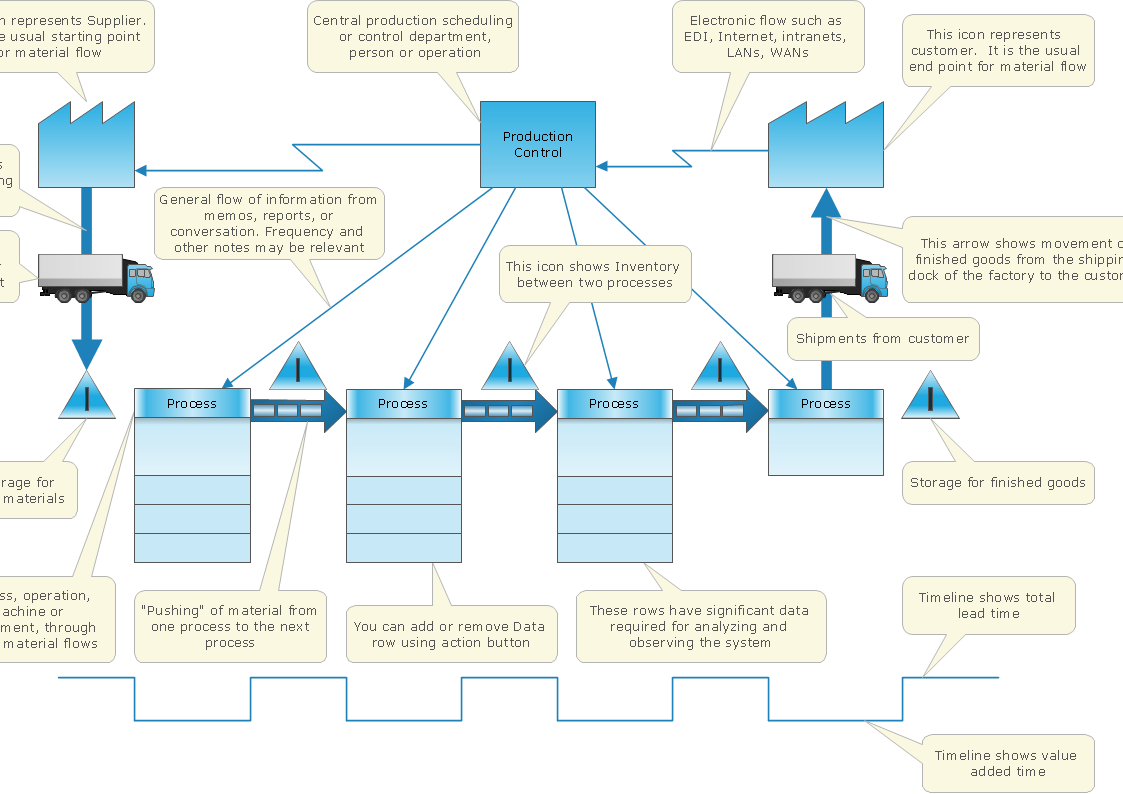

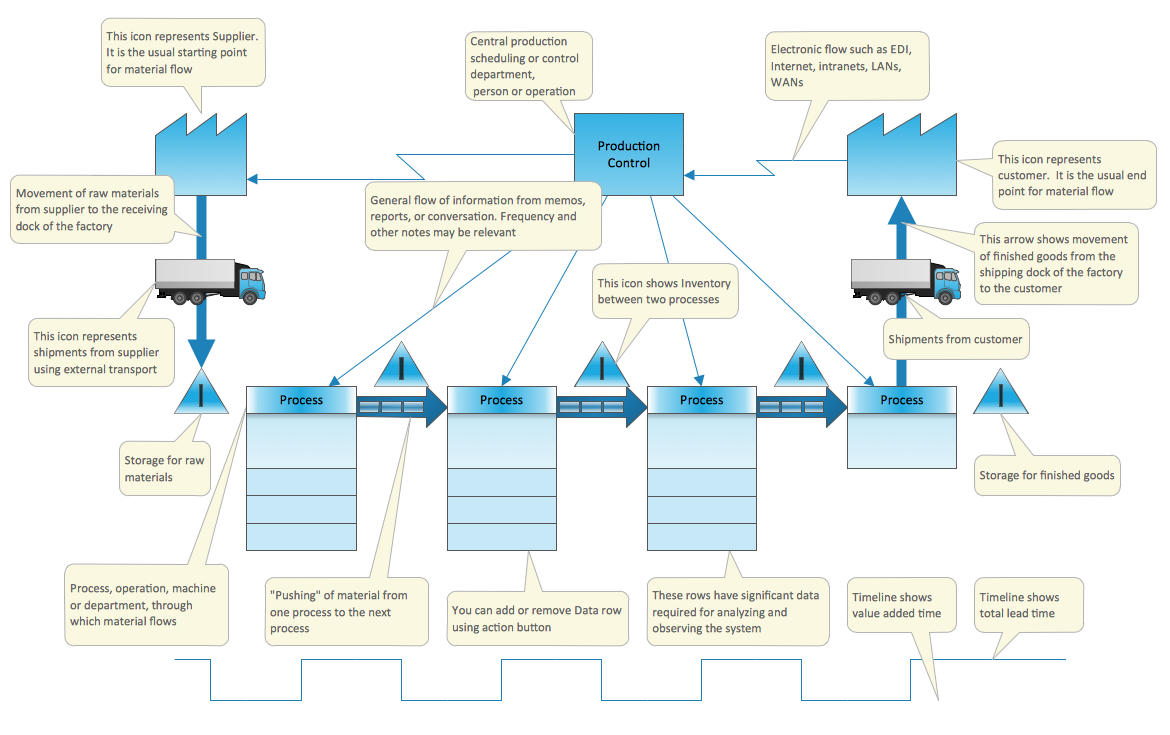

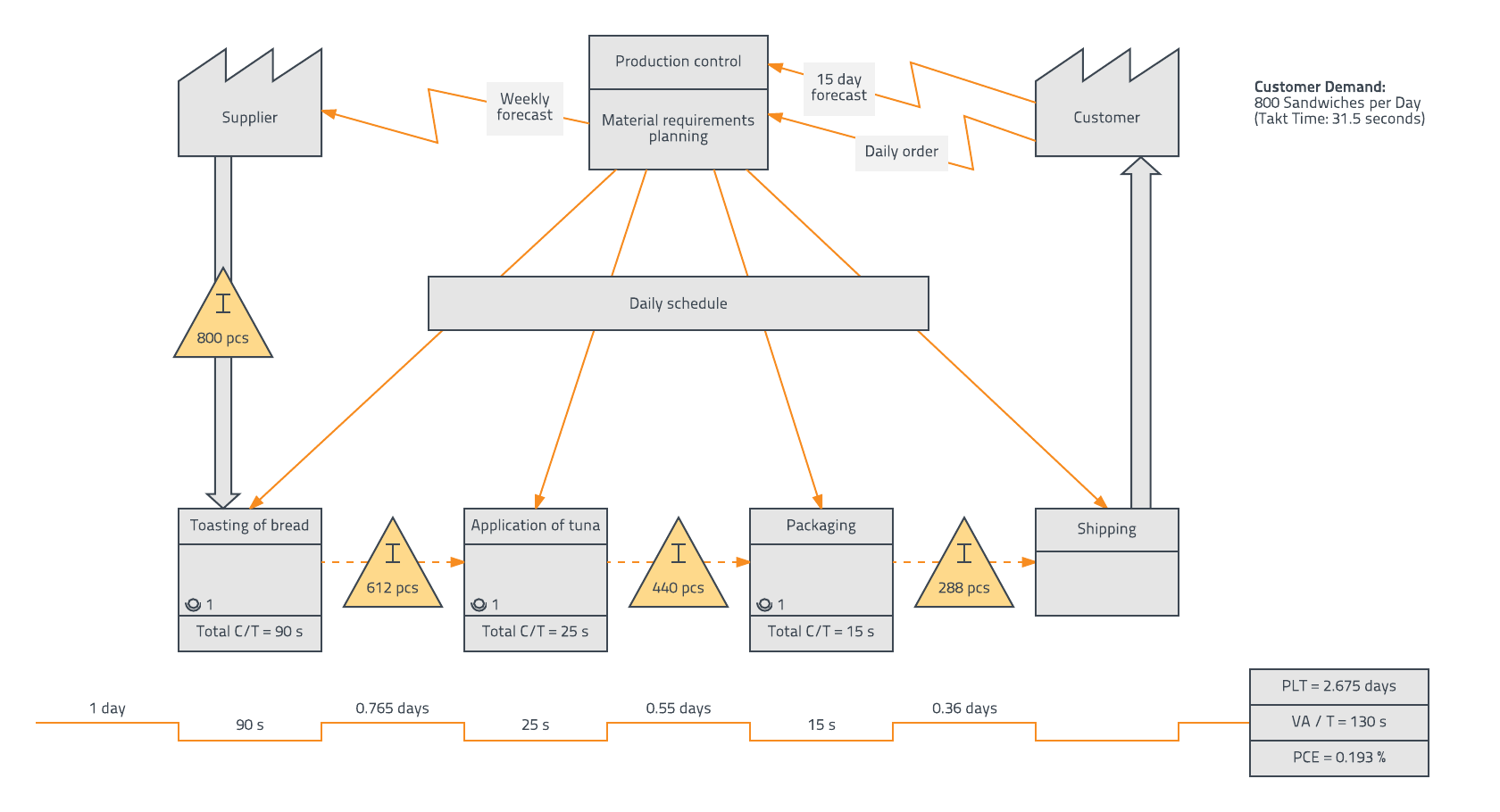

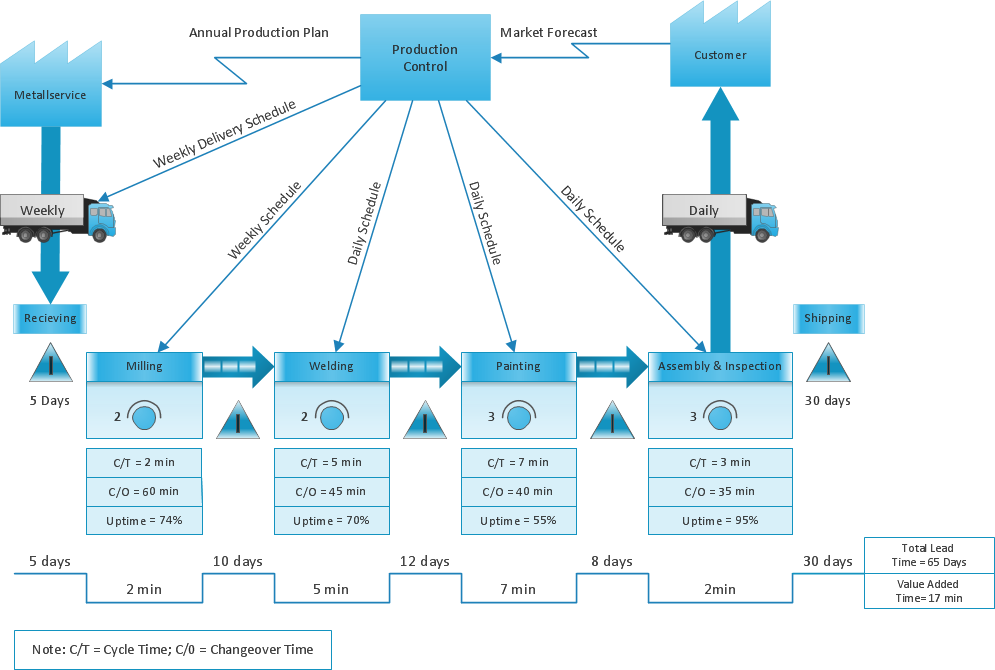

Use standard value stream symbols and icons so that others who trained in value stream mapping could understand. The value stream map provides a basis for identifying unnecessary work (‘muda’), particularly with regard to: The best way to understand value stream maps is to look at some examples of value stream maps.

A value stream is the set of actions that take place to add value to a customer from the initial request through realization of value by the customer. Study the value stream mapping examples given below to get into a full insight on the concept. Value stream mapping maintains that focus.

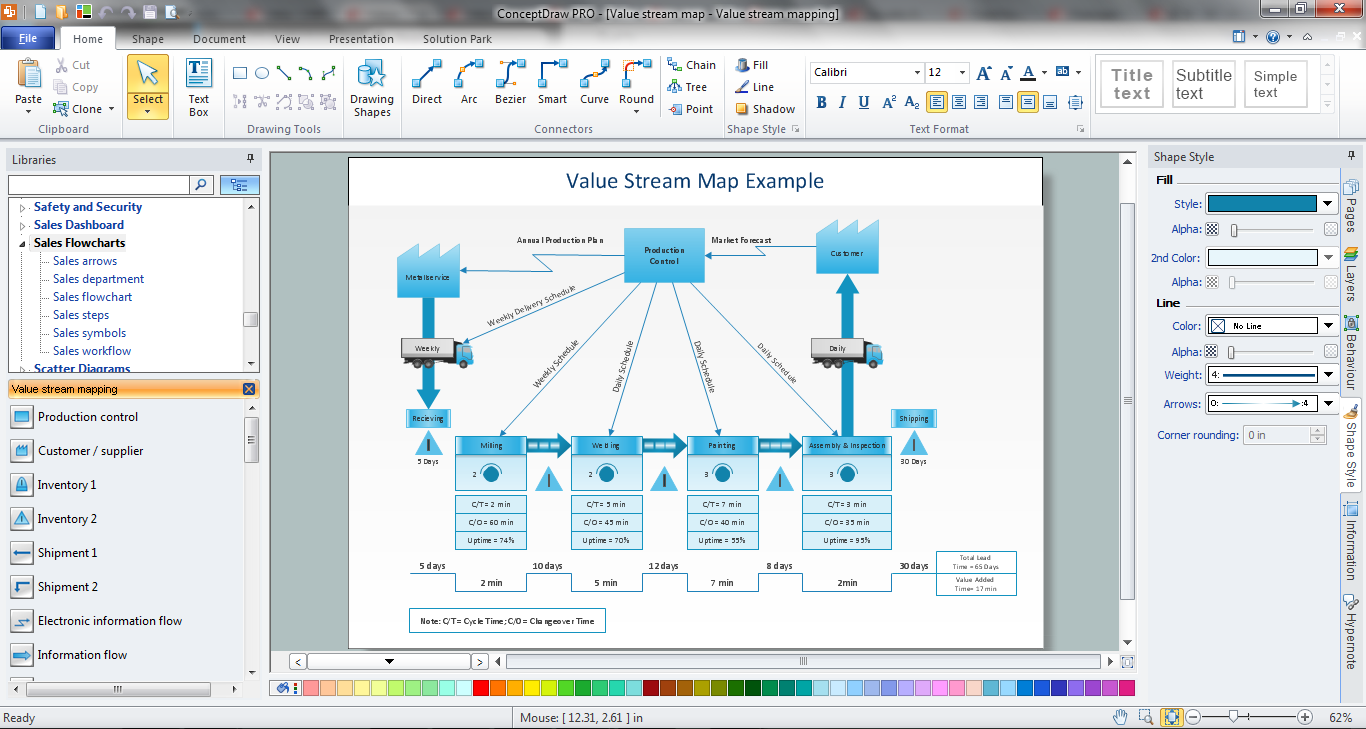

In this video, we explain the basics of value stream mapping in a step by step manner, so that a beginner can also learn to create a vsm in his / her company. It offers a detailed overview on everything. In this course, you will learn how to draw your first value stream map using microsoft visio.

The timeline summary box appears after the last process shape on the timeline and. How to do value stream mapping:

![Valuestreammappingfreeexceltemplates [Extra Quality]](http://leanmanufacturingtools.org/wp-content/uploads/2012/05/Slide13.jpg)